Masuma has expanded its range of engine components with a new addition — complete Timing Belt Kits designed to ensure precise valve timing and long-term engine reliability.

Why the Timing Belt Matters

The timing belt synchronizes the rotation of the crankshaft and camshaft(s), ensuring valves open and close at the correct moments during the engine cycle. It operates under continuous mechanical stress, which is why timely replacement is critical.

For most vehicles with timing belts, manufacturers recommend replacing the belt every 60,000 to 100,000 kilometers, depending on the model. Ignoring this schedule risks sudden belt failure — and on many engines, a broken belt can lead to catastrophic internal damage, including bent valves, damaged pistons, and a ruined cylinder head. Often, the only solution is a complete engine rebuild or replacement.

What’s in a Timing Belt Kit?

A proper timing belt service includes more than just the belt. Tensioners and idler pulleys must also be replaced. A worn tensioner can’t maintain the required tension, and aging pulley bearings may seize, leading to premature belt failure.

Masuma Timing Belt Kits provide a complete, ready-to-install solution:

- Guaranteed compatibility of all parts,

- Time savings and installation convenience,

- Consistent quality from a single manufacturer.

Each kit includes a timing belt, pulleys, and tensioners, tailored to the engine’s valve timing system.

Masuma Timing Belt Kits

Timing Belt Materials

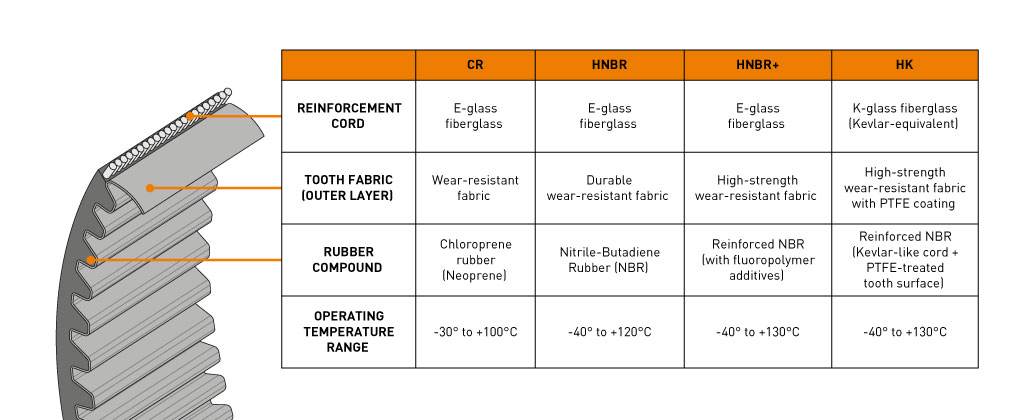

Masuma offers timing belts made from four high-performance materials, chosen based on engine design and thermal load.

- CR (Chloroprene Rubber / Neoprene)

- Resistant to oil, ozone, and aging

- Heat tolerance: up to 100 °C

- Ideal for low-load, low-temperature engines

- HNBR (Hydrogenated Nitrile Butadiene Rubber)

- Improved durability and thermal resistance

- Heat tolerance: up to 120 °C

- Suitable for modern engines with higher thermal loads

- HNBR+ (Reinforced HNBR with Fluoropolymers)

- Enhanced temperature resistance: up to 130 °C

- Better longevity in high-demand applications

- HK (Kevlar-reinforced HNBR with PTFE Coating)

- Kevlar-like K-class tensile cords for extreme strength

- Teflon-coated tooth fabric for superior wear resistance

- Designed for high-performance or high-duty-cycle engines

Timing Belt Pulleys

Masuma pulleys are engineered from durable, wear-resistant materials, selected for specific engine configurations. Features include:

- Housing materials:

- Steels: 20#, 45#, SPCC, SPCD — offering rigidity and longevity

- Engineering plastics: PA66-GF35, PA6-GF50 — lightweight, temperature-resistant

- Precision bearings: sizes 6203, 6006, 6002, 6303, 6007

- High-performance greases: Kyodo Super N, Kyodo ET-P, KLUEBER 72-72 — for smooth, quiet operation

- Seals made from NBR (nitrile rubber) and ACM (acrylic rubber) — ensuring effective protection against contamination

- PA46 plastic for outstanding thermal and mechanical performance

- Aluminum alloys (AlSi9Cu3, ADC12) for corrosion resistance and reduced weight

Accurate factory-set spring force helps prevent belt slippage, ensuring consistent valve timing and smooth engine operation.

Use the Masuma online parts finder to choose the right Timing Belt Kit for your vehicle — and keep your engine running reliably with OE-level performance and peace of mind.