A new addition to the Masuma engine parts lineup: timing belts.

The toothed timing belt synchronizes the operation of the crankshaft and camshaft(s), ensuring that the intake and exhaust valves open and close at the correct moments. This makes it a critical component for engine performance and reliability.

Why Timing Belt Maintenance Matters

The timing belt is subjected to continuous mechanical loads, which is why its service life is strictly specified by the vehicle manufacturer. For most engines with a belt-driven timing system, the replacement interval is around 100,000 km, while certain models may require replacement as early as 60,000 km.

Neglecting scheduled replacement can result in sudden belt failure. On most interference-type engines, a broken timing belt causes the pistons to collide with the valves, leading to severe internal engine damage. In many cases, repairing such an engine is either technically impossible or economically impractical. Timely replacement of the timing belt is therefore the responsibility of every car owner.

When performing replacement, it is crucial to select a high-quality timing belt—one that will reliably deliver the specified mileage without stretching, delamination, or premature wear.

MASUMA TIMING BELTS

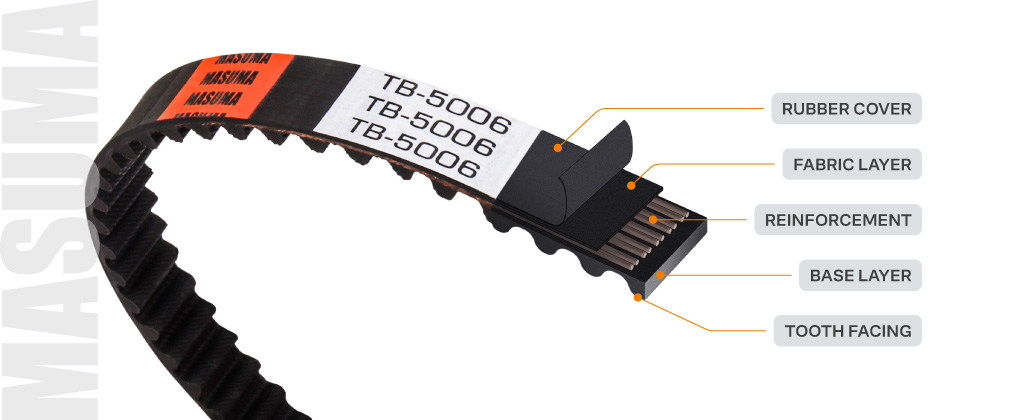

The multilayer construction of Masuma Timing Belts ensures durability and strength, with each layer serving a specific function:

Rubber Cover

The outer wear-resistant layer is made of hydrogenated nitrile butadiene rubber (HNBR), a high-grade elastomer manufactured in Japan. It protects the belt from overheating, dirt, ozone, moisture, and oil.

Fabric Layer

A coarse-weave, high-strength fabric provides resistance to roller friction and minimizes the risk of delamination, securely bonding the outer cover to the inner layers.

Reinforcement

High-modulus fiberglass cords give the belt excellent tensile strength and prevent elongation, maintaining dimensional stability throughout its service life.

Base Layer

The flexible HNBR rubber base absorbs vibrations and provides a durable matrix for the belt teeth.

Tooth Facing

A ribbed nylon (polyamide PA66) coating with a low coefficient of friction reduces tooth wear, ensures precise engagement with pulleys without slippage, and minimizes both operating noise and tooth abrasion.

Advantages of Masuma Timing Belts:

- Wide operating temperature range: −40…+150 °C

- Long service life with excellent wear resistance

- High tensile strength and rigidity reserve

- Flexibility and vibration resistance

- Resistance to oil, ozone, and aggressive environments

- Dimensional stability throughout the entire lifespan

- Low friction and quiet operation

Find the right timing belt for your vehicle with the Masuma Parts Finder.