Shock absorbers in a vehicle’s suspension system influence not only ride comfort and handling but also braking performance and ABS operation by maintaining reliable tire-to-road contact.

Over time, many car owners begin to notice oil mist or leaks on their shock absorbers — soon followed by knocking sounds during driving. The question arises: what replacements to choose? The Masuma product range includes over 400 models of shock absorbers and struts. Importantly, they are not only dimensionally compatible but also replicate the design and specifications of the OEM parts, preserving the original suspension characteristics. That’s essential, as shock absorbers that look similar on the outside can vary significantly in internal construction.

Hydraulic and Gas-Charged Shock Absorbers

Modern vehicles use both hydraulic (oil-filled) and gas-charged (gas-oil) shock absorbers — and Masuma manufactures both types.

Conventional hydraulic shock absorbers offer a smooth, comfortable ride. However, under intense use — such as prolonged driving on rough roads — they can experience temporary performance loss due to oil foaming. To prevent this, a gas charge is added to the design, resulting in a gas-charged shock absorber. While more expensive, it delivers more stable performance under extreme conditions.

Automakers choose the appropriate type based on the vehicle’s intended purpose. Masuma adheres to the original equipment specification: if the factory setup used gas-charged shocks, the Masuma equivalent will be gas-charged as well.

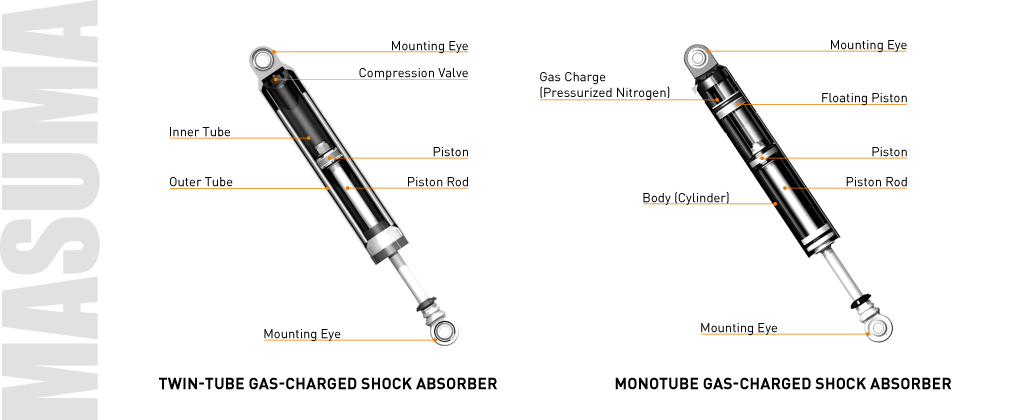

Twin-Tube and Monotube Shock Absorbers

Shock absorbers also differ by design: they can be either twin-tube or monotube.

Twin-tube shock absorbers are essentially a “tube within a tube.” The outer casing offers protection against physical damage, though it limits heat dissipation. This design is compact and typically installed rod-up.

Monotube shock absorbers feature a single tube that serves as both the working cylinder and the housing. They provide superior cooling and oil control under stress, but are bulkier and more sensitive to external damage. They can be installed rod-down, which is often preferred in high-performance and racing applications.

As with gas charging, the choice between twin-tube and monotube designs depends on the vehicle’s suspension layout. Twin-tubes are favored for their compact size and robustness; monotubes are chosen when thermal stability and performance are the priority.

Masuma shock absorbers follow OEM construction and performance standards.

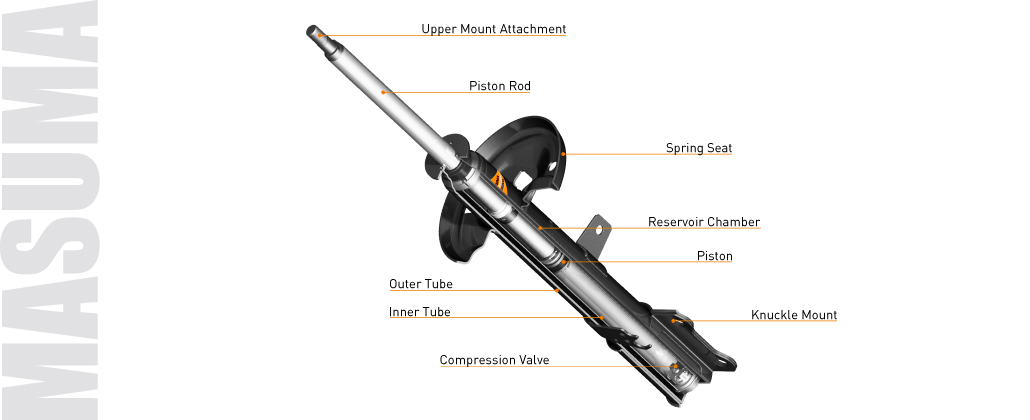

Struts

In some suspension types — most notably MacPherson strut designs — the shock absorber not only dampens vertical movement but also provides structural support and absorbs lateral forces. This component is known as a suspension strut.

The key difference between a strut and a standard shock absorber is the mounting method. The lower part of the strut is bolted directly to the steering knuckle, whereas a shock absorber is typically connected via a rubber bushing. The upper mount of a front strut also features a bearing that allows it to rotate with the wheel, unlike a regular shock absorber. Struts usually have thicker piston rods due to the increased mechanical load.

Extending Shock Absorber Lifespan

To ensure a long service life for your shock absorbers, it’s important to regularly inspect the protective components — dust boots and bump stops. These parts are the first to deteriorate under the effects of road chemicals and abrasive debris from wheel wells. Replacing worn-out boots or stops in time can significantly prolong the life of your shocks.