Brake discs are critical for the brake system as they slow down your vehicle due to brake pad friction. The braking efficiency greatly depends on brake disc condition: even some tiny runout makes your braking path several meters longer. And disc quality directly affects your safety. Therefore, a lot of money and effort has been invested in the production of Masuma brake discs. And now we offer car owners really high-quality spare parts.

PLANT

Masuma brake disc plant features cutting edge equipment: lines for vertical and horizontal molding, casting cooling, machining. Most of the operations are automated, which minimizes the likelihood of rejects.

MATERIAL

High-strength gray cast iron G3000 class (Brinell hardness: 187–241 BHN) with graphite additions is used for Masuma brake disc production. This alloy is highly resistant to extreme loads and has high thermal stability: it withstands overheating and rapid cooling. Complies with SAE J431b and ASTM A159 standards.

GEOMETRY

High-precision castings with minimal tolerances (up to several microns) guarantees the correct disc configuration and no vibration during operation. Every Masuma brake disc is precisely factory balanced and dimensionally tested.

SPRAYING

For vehicles with large open rims not just efficiency matters but also the appearance of brake assembly. Masuma produces brake discs with high-temperature black coating on non-working surfaces specifically for such vehicles as these disc always look the best.

COATING

Discs are coated with an oil-free anti-corrosion compound which guarantees their safety even while storing in high-humidity conditions. The oil-free protective compound does not affect brake pad performance, so it does not need to be removed when the discs are installed on the vehicle.

LABELLING

Each Masuma brake disc has laser engraved labelling:

- corporate logo,

- part number,

- batch number,

- minimum permissible thickness.

QUALITY CONTROL

Each Masuma disc batch is tested according to TUV, ABE, KF2-GVO 1400/2000, TS16949, ISO 9001: 2000 and Masuma proprietary standards.

- Chemical analysis makes it possible to evaluate alloy quality, its strength and other characteristics of the material.

- Spectral analysis shows the accuracy of alloy formulation during casting.

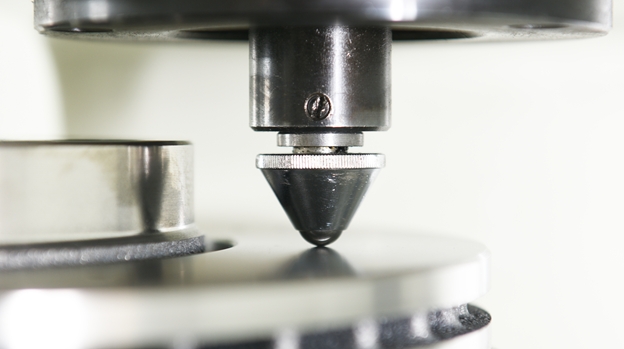

- Abrasion resistance test checks the resistance to abrasion in different braking conditions including different ambient temperatures.

- Geometry and hardness measurements confirm compliance with the specified parameters. Masuma brake disc dimensions are completely identical to the original ones.

Masuma recommends installing new brake discs in combinations with new brake pads to increase the assembly’s performance and service life.